i need some cool pics of 88 mm flak 36 or 18

tnx

well it’s ok, but i am building a diorama, and need some pics of flak 88 with suroundings

also i am looking for a pic of flak from a stalingrad 1942, that has kill marks for planes, tanks and bunks on the armor plate

8,8 cm Flak 18 used as field artilley piece in the early stages of Barbarossa by the Totenkopf div.

great pics

also i am looking for a pic of this flak

Are you just building one for Stalingrad or flaks from other campaigns? Also try searching google.

i build several flaks including this… i cant find any photo of this on the google but i know i have seen photho of this flak somewhere…

Small pic, hope it will help.

There are a couple of nice color ones in the ww2incolor gallery, did you check it yet?

already have them… only i need one more pic and it is of an flak that i posted

Flak 36 in a Eisenbahnpanzerzuge ( armored convoy train)

Check the notable aircraft and tank kills.

Nice video of the 8,8 cm Flak 18 in action in the italian front, 1943.

Hello to all!!!

Flak 18 in the night !!!

By ebay old auction…

Good one, we want more ¡¡

Hi.

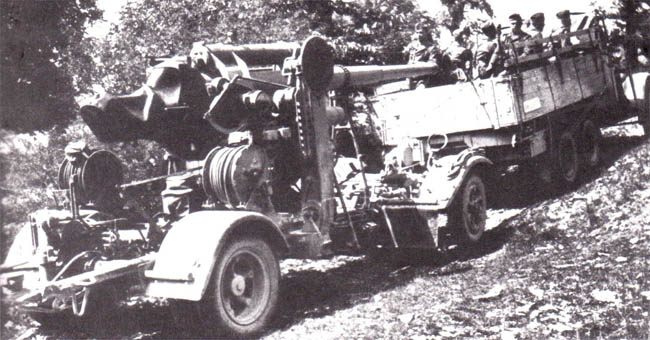

Transport:

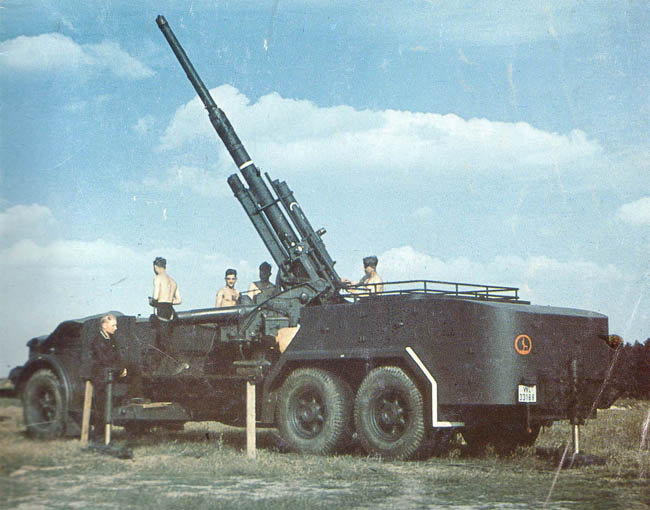

And a nice color pic:

Yours

tom!

Very good one in color ¡¡

The gun is a Flak 36,… you know the name of that truck ?

Hi.

This is a 8,8 cm Flak 18 with a barrel of the Flak 36 mounted on a Omnibus-chassis made by VOMAG (Vogtländische Maschinenfabrik AG at Plauen). A total of between 21 and 24 vehicles was built in 1939/40.

The vehicles were used by the 1/42nd aa-regiment planned as heavy aa-battery for the"Führer-Begleitabteilung" for the attack on France 1940. Due to weight problems the vehicles were combat-ready in late 1940.

The 1/42nd aa-regiment had 3 batteries with 4 gun trucks, a command truck with the Kommandogerät 36 and a support truck towing a FuMG 39 T each.

Yours

tom!

Very good Tom, danke.

Hi.

This text is a translation of the first 6 pages of an interesting two-part article in the german “Waffen Revue” issues 121 and 122. I´ll translated it for a friend of mine but I think it´s also a good idea to add it here.

I´ll try to add further parts if my time allows further translation works.

Due to the restrictions in the ammount of characters in one post I have to part the text.

Some parts of the following translations are made by babelfish as my vocabulary regarding special terminology is limited. So please excuse some badly translated parts.

Subcaliber ammunition of the

uprated 8,8 cm AA-gun 18, 36, 37 and 41At the time of introduction in 1933 the 8,8 cm Flak 18 was classified as the most advanced gun used against air targets at heights up to 10 km and against ground targets at a range up to 15 km. The data evaluated and computed 1933 in Meppen state naturally nothing over the hit accuracy. Only if one regards the data concerning the 50% dispersion, one recognizes the difficulties to accomplish an arranging of the guns in such a way that on this distance still hits could be obtained, what is extraordinarily difficult with moving targets.

From the tables shown here one knows the achievements of the cannon on different distances and target heights, also against air and ground targets, which applied to the improved Flak 36 and 37.

(ballistic table of the 8,8 cm HE grenade L/4,5 with head fuze against air and ground targets)

Already soon, after the cannon had found its first employment in the Civil War in Spain, at least quite after the outbreak of the 2nd World War, the long flying time of the projectiles was criticized, what became unfavorably apparent particularly when fighting against air targets.

A first remedy was created by the development and introduction of the 8.8 cm Flak 41, which worked outstanding. An increase of the efficiency in relation to the previous guns was reached mainly by the fact that the length of the cartridge was increased from 570 mm with the Flak 18 to 855 mm with the Flak 41 and thus the increase of propellant weight from originally 2.5 to 2.9 kg (depending upon type of powder) to 5,5 kg. Thus the firing heights and also the range in ground combat could be increased by approximately 5 km.

Despite these successes the disadvantage of the relatively long flying times of the projectiles could not be repaired with conventional means. A reinforcement of the propellant, approximately by increase of the energy content or the quantity of the powder, would have developed a gas pressure after the ignition of the propellant, which the pipes and the bottom parts of the breech would not have withstood any longer. With the Flak 41 the development was anyway already pushed to the border of the feasible.

(ballistic table of the 8,8 cm AP grenade 39 against ground targets, Flak 41)

A solution of the problem was seen in the creation of so called subcaliber ammunition, from which there were mainly three possibilities. The first, using the cartridge of larger caliber down-calibrated at the case mouth so that the full pressure could affect a projectile of smaller caliber, as one did it for example with the anti-tank rifle Panzerbüchse 38 (from 13 mm to 8 mm), failed here from the reasons specified already.

Thus only the second way with the so called “Treibspiegel-Geschossen” (sabot projectiles) and the third way with the so called “Flansch-Geschossen” (flange projectiles) offered themselves.

With the sabot projectile a grenade of smaller caliber supported by a guidance ring at the head and a sabot at the bottom are used, which support the smaller diameter projectile inside the gun barrel and drop off after leaving the barrel, making the projectile substantially lighter. After igniting the gas pressure, that was originally necessary for example for a 8.8 cm projectile, now effects a much smaller and lighter projectile highly increasing the efficiency. On the disadvantages will be reported in the following.

With the flange projectile the guidance ring is not separated from the smaller projectile after leaving the barrel but pressed completely flat to the rear on the projectile inside the gun barrel. This is however only possible using a tapered bore barrel or attaching a tapered bore barrel to a normal barrel, in which the flange is pressed to the projectile.

The problems are very various with both ways. A report, which the department Gercke from Krupp wrote dated 05.08.1944 under the title "Regarding the question of the increase in efficiency using sabot projectiles (Tsp.-Geschosse) and flange projectiles (F-Geschosse)”, gives an overview. Since the report is very extensive and contains many technical computations, this report is shown only in parts in the following:

“

The Tsp. - and F.-projectiles are means for the increase of the gun efficiency by combination of internal-ballistic measures and appropriate shaping of the projectiles. In both cases the basic idea - only subcaliber Tsp.-projectiles are to be regarded here - is that the energy of the propellant is transferred on a lighter projectile of smaller caliber, and so a high muzzle velocity is obtained. The Tsp.- projectiles can be fired from existing barrels, for the F.-projectiles special conical barrels or conical pieces of disalignment are necessary.In the following an overview of should be given, which profit can be expected exterior ballistically and at penetration performance and which criteria for the evaluation of the Tsp.-projectiles and F.-projectiles are substantial, in order to receive a basis for future evaluation directions.

Yours

tom!

Hi.

Part 2:

- Sabot projectiles:

The construction of the Tsp.-projectiles differs by the different kinds, how the replacement of the sabot and the guidance ring is reached. One-piece and multi-piece sabots have been developed. As appropriate and useful solutions regarding the sabots the following developments turned out:

a) “Näpfchenbefestigung” (cup-type attachment)

b) Separation by gas pressure chamberRegarding the guidance rings… [not given]

With the basic idea, the flying off sabot and guidance ring, two main problems are given to the construction:

a) Muzzle brake security: Fundamental a muzzle brake-safe sabot is to be demanded, since for a sabot-safe muzzle brake no solution could have been found so far.

b) The Flying-off of the sabot in a certain distance from the gun and the endangerment of the own troops due to it has to be seen as fundamental disadvantage.There were trials to build the sabot in a way that it dissolves into many small parts, which represent no endangerment.

On a totally different way a solution is tried, an “airworthy sabot”. Because the sabot together with the guidance ring forms as body designed as tubular projectile, the air resistance should to be lowered and and its flight characteristics should be improved in such a way that it obtains a flying range going beyond the area of deployment of own troops.

As advantage of the construction there is a lower need for raw materials for the projectile and thus a saving result in particular at high-quality alloy elements compared to the full caliber projectile.

Regarding the manufacturing the sabot projectiles are favorable by the facts that:

- for the cores of the sabot projectiles actual production armor-piercing shells of smaller and middle calibers can be used, for which the already run-in mass production companies of the armor-piercing shell can be consulted;

- the manufacturing of the sabots and guidance rings can be taken over by manufacturing works, which do not have to be particularly specialized in projectile manufacturing.

Regarding inner balistics no special measures are to be met for firing sabot projectiles from existing barrels, however it is to be examined whether the existing projectile spin is sufficient. From a given barrel generally with same charge the same muzzle velocity is not reached as with the full caliber projectile. This is to be particularly considered for a comparison from penetration performances: The reason lies in the fact that the efficiency drops with a lower projectile weight. General data for the size of this dropping cannot be concerned so easily, since here also the load density plays a role.

Regarding outer ballistics it is favorable for the sabot projectile that the driving bands are missing at the projectile, and also that the cylindrical projectile part necessary with normal projectiles for the guidance can be omitted, so that the projectile can be given a aeordynamically favorable form to the projectile with direct transition from a conical head to an ogival tail. Thus a favorable form value and therefore a reduction of speed waste is reached. Compared with a full caliber projectile of the same small weight and thus the same muzzle velocity the speed waste of the sub-caliber sabot projectile is smaller because of its larger cross section load.

A certain disadvantage consists of the fact that the replacement of the sabot from the projectile could possibly give cause for oscillating of the projectile and thus for a bad flight. However this difficulty might be generally repaired with the sabot constructions described above.

A utilization of the exterior ballistic possibilities given with the sabot projectile appears particularly important for aa-guns. Improvements of an aa-gun in ballistic regard means: Reduction of the flying time for given target distance or enlargement of the range with given flying times.”

In the document some computations and examples follow. After that it continues:

„That means: With the sabot armor-piercing shell a substantial increase of penetration performance is to be expected compared to the full caliber armor-piercing shell only in those cases, where a suitable full caliber armor-piercing shell of that caliber doesn´t exist yet.

From the point of view of the armour penetration a use of sabot projectiles comes thus into question either to the increase of the penetration performance of existing guns or with the middle or large caliber in the cases, in which for this still no good full caliber armor-piercing shell is available and in which criteria of the saving in raw material and possibly better manufacturing possibilities are important.

- Flange projectiles

Constructional the flange projectile has some disadvantages due to the multipartness compared with the sabot projectile. The manufacturing is somewhat more difficult due to the multipartness, however it might not to be concerned, since the associated cannons will be present only in limited numbers, as the f-projectiles production will not be a projectile manufacturing mass production as for other guns.

The barrel diameter redcution necessary for firing f-projectiles is reached using conical barrels or a tapered bore barrel extensions.

Therefore there are some questions regarding inner ballistics and construction of the barrels and barrel extensions needed including shape (favorable form of the mantlett of the barrel or extension) and material (consideration of the increased wear with the pressure of the small muzzle diameter to the deforming flanges). Therefore the increased wear and life span of the barrels becomes the main problem, in connection with the question of the replaceability of the extensions.

It turned out that with rising barrel wear the muzzle velocity does not drop. Thus the life span is to be judged either by the increase of the dispersions or the reduction of penetration ability. The principle of the f-projectiles appears in principle limited in application to smaller calibers.

Outer ballistically a certain difficulty arises with the f-projectiles by the fact that due to their multipartness a shift of the balance point can occur when not laborated accurate, which lead to a bad flight. This difficulty does not seem to be completely overcome yet, so that occasionally individual shots occur again and again, with which the projectiles deviated without recognizable reason from the intended flight path.

With increasing wear of the barrels an increasing decrease of speed of the projectile arises as the flanges are not squeezed up to the core diameter.

The effect at the target of HE-projectiles is naturally low due to the limitation of the f-projectiles for the use with small caliber guns. Regarding AP-projectiles only full-caliber construtions have been tested jet. For lager calibers, e. G. 12,8/9,6 cm, a construction with a sub-caliber core built as APHE-projectile seems to be possible.

Basically it can be stated that an APHE flange projectile with comparable ability to a standard full-caliber APHE-projectile doesn´t exist jet. The main problem is that a possibility to connect the cap and the front flange with the core projectile without a decrease of stability of the core projectile hasn´t been found jet.

A further suggestion on the attachment of cap and front flange without attenuation of the core is attaching the cap using a thin coat pulled over the core in its whole length.

For penetration computations the following criteria are to be regarded in principle:

- It is appropriate to consider a speed drop of the projectile corresponding to a certain degree of the wear of the barrel or adapter.

- As with the armor-piercing shells a certain decrease of the penetration ability of the projectiles from the serial production in relation to the maximum values obtained during the first tests has to be considered.

- It appears justified not to use the full projectile weight since the flanges contribute only partially to the penetration.

An employment of the f-APHE- shells, for which special guns are necessary, is applicable mainly for reaching the high penetration demand of 200 mm below 60° up to 4000 m. Which achievements are necessary under the condition to reach a penetration performance comparably with that of the 7.5 cm and 8.8 cm armor-piercing shells, shows the following table, which was provided considering the points specified above.

(table missing)

One can see that the that the demanded conditions quite still seems attainable with acceptable gun loads and muzzle velocities.”

So far thus the paper of Krupp, which sounds actually not very encouraging.

Yours

tom!