Hi.

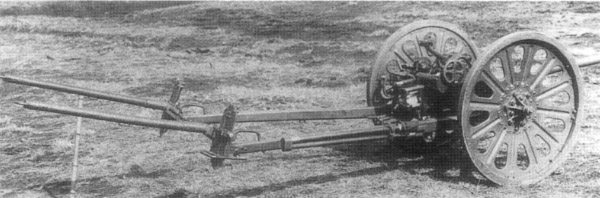

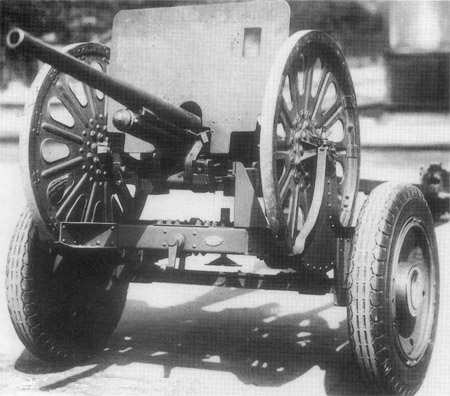

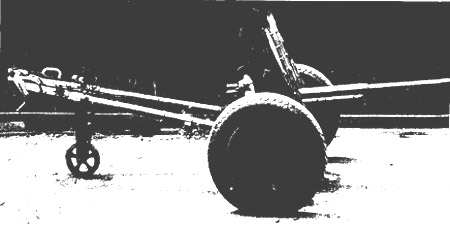

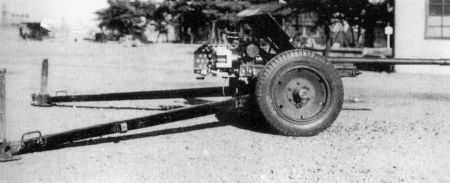

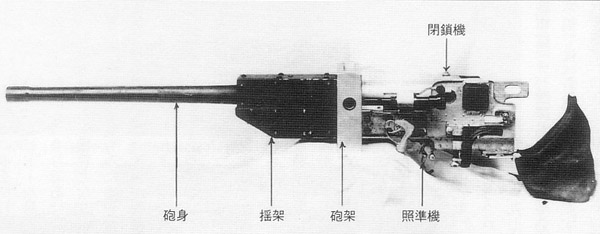

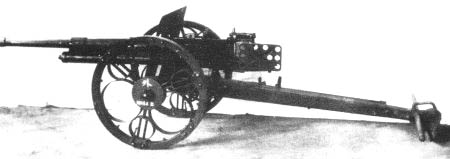

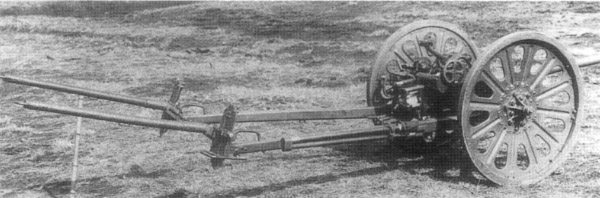

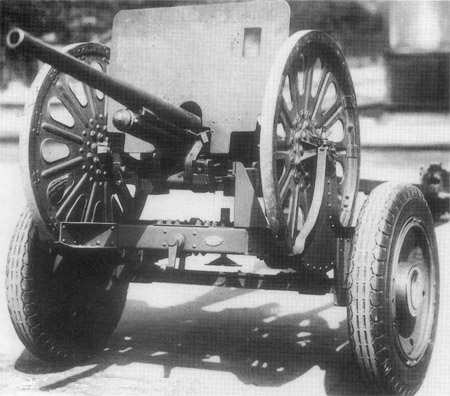

Type 94 37 mm rapid fire infantry gun:

This gun was planned from 1933 on as replacement for the type Taisho 11 37 mm infantry gun. It should be used as infantry gun and anti-tank gun. Other specifications were low weight for easy handling, an armour shield and transport with a light towing vehicle or 4 horses.

The first prototypes were built in 1934 with rubber tires for high transport speed. During tests the tires were found very vulnerable for small arms fire so they were replaced by wodden or metal wheels with rubber band.

The gun worked semi-automatic making a maximum rof of 20 rpm possible, 15 rpm cyclic. The total weight was 327 kg. This was found acceptable. The 4 mm thick shield was often removed to spare the weight making the gun more mobile. Two hande bars could be attached on the lafette for man transport.

In 1936 the gun was first used in China. The 0,49 kg type 95 he-round was found useful against soft targets on ranges up to 5000 m. Due to the lack of armoured vehicles in the chinese forces the ap-abilities were not necessaryly needed.

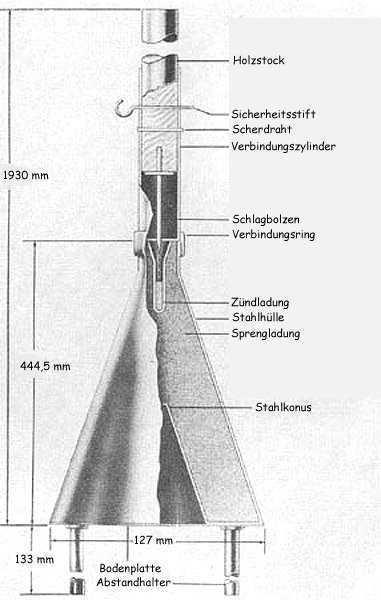

Shooting range tests showed a problem with the early ap-round lowering the penetration ability to 20 mm/90° 350 m. In the mid-thirties additional research was made on this problem leading to a new projectile introduced around 1937 giving the gun a penetration ability of 40mm/90° on 300 mm and 25 mm/90° on 900 m.

The type 94 gun was also used in a modified version as type 95 37 mm tank gun on the type 95 light tank Ha-Go and the type 94 tk special tractors and the early type 97 tankettes Te-Ke.

The Nomonham Incident showed the inefficiency against modern medium tanks as used by the Soviets. The high rof made the gun very useful against light ands medium field fortifications but due to the small caliber almost useless against heavyly fortified or concrete targets.

As the road transport speed was limited due to the wheels used a special transport carrier was developed in the late 1930´s. The gun was fixed on this carriage and then a road speed of up to 52 kph instead of 25 kph was possible.

A gun section with the type 94 rapid-fire infantry gun consisted of 11 men, leader, gunner 1 (giving direction), gunner 2 (directing gun), 2 loaders, 6 ammunition soldiers, also for close defence, and 1 driver. A gun platoon was two gun sections, section commander, 2 runners.

A Battalion anti-tank/infanry gun company consisted of two gun sections, company headquater ( Commander, 7 runners and orderlies, 1 NCO personnel administration, 1 NCO supply, 1 NCO arms and equipment, 2 medics), Ammunition platoon (commander, 20 NCO´s and men) and observation section (1 NCO, 6 men).

Yours

tom!