That’s fairly typical of the one big problem with German engineering - never use one simple part where five complicated ones will do…

Could you be a little bit more specific about those problematic German objects previously mentioned in your reflection, my dear Mr. Pdf 27? You see, although certain examples of unnecessary complicated devices used within German Armed Forces inventory are well known (for example that curious Maybach OLVAR, hydraulically operated pre-selective gearbox) we do have a complete surfeit of opposite examples as well.

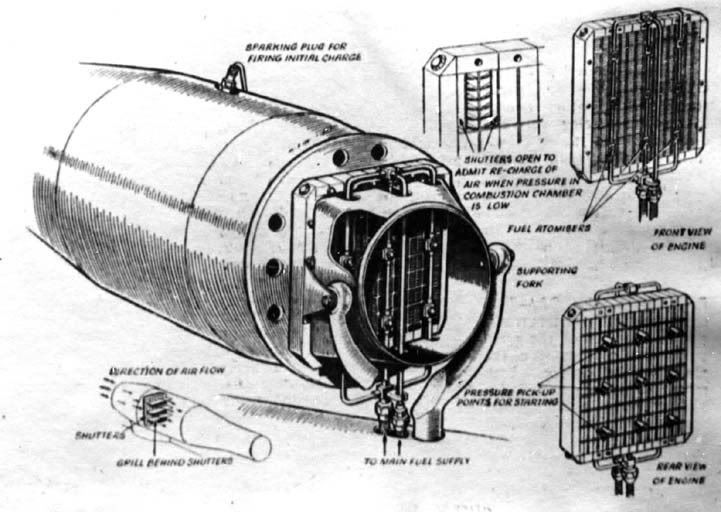

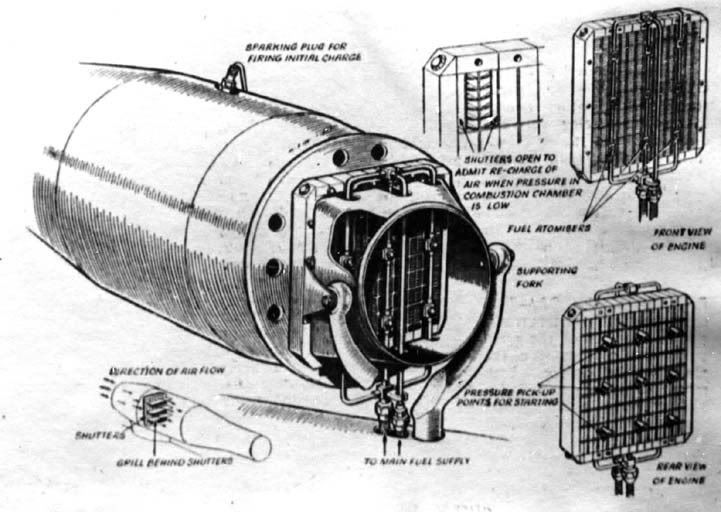

Argus AS-014 – an almost perfect example of engineering simplicity

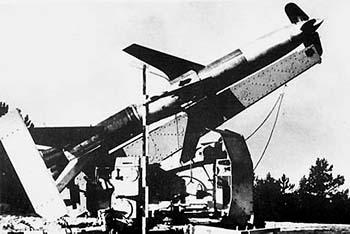

For example, Argus AS-014 pulsejet engine certainly is – as far as I know – almost a perfect example of so called minimalist engineering design. This highly uncomplicated propulsion system, invented and patented by ing. Paul Schmidt in 1928, due to its basic simplicity, was very suitable for mass-production at low cost and provided the V-1 a top-speed equal to or slightly higher than most of the allied propeller-driven fighters of the day. As we all know, due to its simplicity there was a possibility for large-quantity production by means of of low-skilled labor. Of course, thermodynamic efficiency of the aforesaid engine was pretty stumpy, but simplicity certainly was accomplished.

Argus AS-014 pulsejet engine

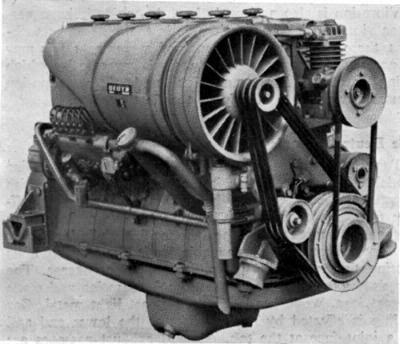

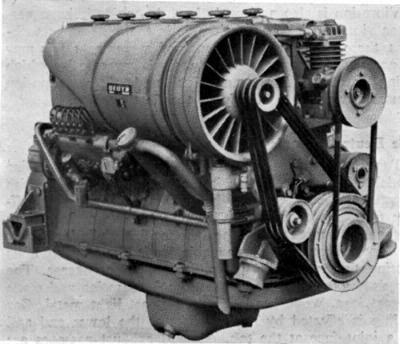

On the other hand, we also have some other bold examples of the German engineering unfussiness that was not only mechanically straightforward, but also highly thermodinamically efficient as well. For example, this almost forgotten, actually highly reliable and robust diesel engine, developed for trucks by Klöckner Humboldt Deutz, actually designed in late1944 and planned for entering operative service in 1945.

KHD F6L514 - 8000 ccm, 125 HP, specific fuel consumption 185 g/HP/hour

As you know, the engine was inherently more reliable because air cooling was immune to either freezing or boiling of the coolant around the cylinder heads and cylinders, as well as to thje loss of the coolant. It was also free from any build-up of corrosive products capable to block or restrict coolant passages. Also less maintenance was required in service, because there was neither requirement to check the cooling medium, for level and factual condition, nor the need to inspect connecting hoses for signs of leakage. Of course, industry was not obliged to produce and supply chemical coolant additives as well.

Furthermore, the whole range of variant fuels was available for this engine. The normal one was gas-oil (Diesel fuel), but the range included fuel oil, kerosene and petrol-lubricating oil mixture in the 90% - 10% ratio! :shock: