Yes and the rare footage of the flight of the Ho-229 V2 prototype. I wish I understood the german in the footage.

Ok I had a PM the other day where the person told me that I am not correct by saying Horten 229.

NOW Panzerknacker what is your opinion about this?

Hu…semantic, teorically would be the powered Ho-IX but it is really unimportant.

http://www.nurflugel.com/Nurflugel/Horten_Nurflugels/ho_ix/body_ho_ix.html

Phew, those guys on that site is not your nicest guys. LOL

Inspired by the ammount of feed back over the me 262 i thought ied tell you guys about the Ho IX. Note the Go 229 desigination some people hear is the Ho 8-229 's name as it was being produced at the Gotha factory for serial production. Go 229 was a media mix up in the infomation department. It is all really the same plane, people just have bad sorces.

The Ho 9 stemed from Goring’s request for a 1000kph X 1000k range X 1000k payload in bombs, ie a fighter bomber.

For some more help

Horten Flugzeugbau…Type #…Aircraft type…RLM Designeation

Ho III…3…Sailplane…Ho 250

Ho IV…4…Sailplane…Ho 251

Ho V…5…Twin-Engine…Ho 252

Ho VI…6…Sailplane…Ho 253

Ho VII…7…Twin-Engine…Ho 226

Ho XI…9…Twin-Turbojet…Ho 229

Note The Ho 229 V3 is still around hiding up in the NASM’s Silver Hill Storage Facility in Maryland USA as of the 1980’s awating restoration… still…

to be continued as i have some free time…

more… The horten brothers talking about there planes

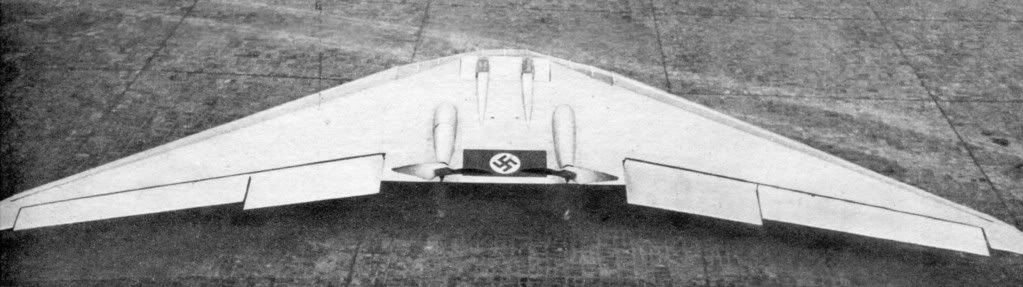

The Ho IX Twin Jet

In a speech before representatives of the aircraft industry, Reichsmarshall Goering had announced that no new contracts would be given, unless the proposed aircraft could carry 1000 kg bombs, fly 1000 km /h, and have a penetration depth of 1000 km; penetration depth being defined as the total range.

The Fighter Division requested that the aircraft also be fitted with 30 mm machine guns, something that would lessen the machine’s efficiency as a bomber.

“We started drawing and calculating without a contract. Our plan was to build two full size prototypes. The initial penetration depth would only be 800 km, since the fuel proof glue necessary for the full wet wing, was not yet available. On the other hand, the smaller fuel load allowed a doubling of the bomb load, so we went ahead and submitted our proposal.”

A contract was awarded with the demand that the first flight be made in six months! Since the jet engine was not yet ready, the first machine would be a glider. The previously deactivated Air Force Command IX was reactivated, and ordered to proceed with the project. Fortunately, the preliminary work that we did without a contract, put us sufficiently ahead, so the six month deadline locked feasible.

There were several reasons for choosing wood as the building material. Duraluminum required more energy to produce; over 3000 KWH, versus less than 3 KWH for wood per ton. The required labor for aluminum production was also much higher; 5000 hr/ton against 200 hr/ton for wood. In addition, aural was difficult to find, and skilled sheet metal workers in short supply. Unskilled workers could easier be trained to work with wood.

Typically, a nose rib was built from a triangular piece of spruce, sandwiched between two plywood sheets, all scrap wood. Production time: 10 minutes. After the glue dried, the rib was simply roused out along a master template in less that 5 minutes. The rest of the wing was built in a similar crude fashion, to pave the way for mass production by unskilled workers.

The main box spar contained all cables and control rods, to free the remaining space in the wing for fuel. That, we planned to pump right into the wing itself, without tanks or bladders. To do this, we needed the fuel-proof glue, that could be used to coat the inside surfaces as well. The glue allowed additional gluing to dissolve and adhere to already coated surfaces, which greatly simplified construction.

The skin was very thick: 17 mm, all plywood; three times the necessary strength. On the production aircraft, this would be replaced by two 1.5 mm plywood sheets, with a 12 mm layer of sawdust, charcoal and glue mix, sandwiched in between. The charcoal in this much lighter skin would diffuse radar beams, and make the aircraft “invisible” on radar.

Finally, should a 20 mm shell explode inside the wing, a relatively harmless hole would result, whereas a metal wing would balloon out and lose its lift.

The H IX wing was designed with 3 geometric and 1.5 aerodynamic twist, to give it the desired bell shaped lift distribution with all controls neutral. The Frise-nose on the elevons had proven to be unsatisfactory, so we decided to use blunt nose elevons instead. The sharply enlarged wing root chord served mainly to eliminate the middle-effect. The maximum thickness line (T-4 line) therefore made a sharp bend in the middle, which resulted in the characteristic pointed tail. As this would affect stability, a test aircraft with large aspect ratio, that had the control surface far outside the test area, was needed. The H Vl would serve this purpose, while other preliminary tests were made with a H II and a H III.

The H IX V-1 took off right on schedule on March 1, 1944 in Gottingen. The small He 45 towplane barely got off the ground, so test pilot Scheidhauer released, and landed straight ahead, after only a short hop. Five days later, he was off again on a snow covered runway behind an infinitely more powerful He 111. He released at 12000 feet, made an uneventful glide back to the airport, then faced problems during landing when the drag chute did not function. As the end of the runway approached, he retracted the nose wheel, and skidded to a stop with only minor damage.

The second aircraft, scheduled to fly three months later, was awaiting its engines, promised in March. Several weeks passed, and then… Disaster!

The engines arrived with an accessory section added to the case, making the cross section oval, and the diameter 20 cm greater! No one had bothered to inform us! Now, just six weeks before the first flight, we were faced with the problem of fitting an 80 cm engine into an aircraft with a 60 cm hole in the spar! It meant that the wing would have to be made thicker.

To maintain the aerodynamic qualities of our design, we would have to increase the span from 16 to 21.3 meters, and the wing area from 42 m2 to 75 m2. Such an aircraft would never reach the targeted performance, even with higher engine thrust. We choose instead to do the best we could with patchwork modifications. The wings remained the same. Another root rib was added 40 cm outside the original, making the center section 0.8 m wider. The new airfoil was 13% thicker than before, and the bend in the T-4 line became much larger. The thicker center section lowered the critical Mach number to 0.75, or a maximum speed of 920 km/in.

The ratio of movement between the control column and the elevons could be reduced to by the pilot for high speed flight. A small high speed drag rudder was supplemented by a larger one that deployed after the smaller was fully extended. Many parts were scrounged from other aircraft left at the test facility in Gottingen. The nose wheel, for instance, came from the tail wheel of a He 177 heavy bomber. We were even able to use the strut and retract cylinder!

The men of Air Force Command IX did their utmost to complete the aircraft before the end of 1944, sometimes working more than 90 hours per week.

I remember that Lt. Erwin Ziller made the first flight about December 18th, 1944, but his log book indicates that the first flight occurred on February 2nd., 1945. I am quite sure the first flight of the H IX was also his first in a jet. Our leaders had little concern for such risks.

Satisfied with the initial flight, the Air ministry ordered 40 aircraft to be built by the Goetha Waggonfabrik under the designation 8 -229.

It appears that the H IX V-2 had flown three or four times before tragedy struck on February 18th. The many versions of the story have a few things in common. The weather was overcast, the ground soft and muddy. The visibility marginal for a test flight, as Lt. Ziller took off, retracted the gear and disappeared. We received a report that one engine had failed, and that the H IX was returning to Oranienburg. Due to the low ceiling, a shallow approach to the airport was initiated. Since the hydraulic pump was on the dead engine, gear and flaps were extended by the emergency compressed air system. Once down, they could no. be retracted. To maintain his glide slope, Lt. Ziller added power. to overcome the extra drag, and found to his horror that he could" no longer maintain directional control; the fully developed drag rudder unable to overcome the asymmetrical thrust. Rather than lose control, he retarded the throttle to land short of the runway. The aircraft touched down in a field, slid into an embankment and flipped over, crushing its pilot.

The Third US Army Corps reached the Goetha plant on April 14th 1945. Here they found the H IX V-3 intact and nearly completed, and also the V-4, V-5 and V-6 in various stages of completion. The Ninth US Armored Division found the H IX V-1 in good condition near Leipzig. Its fate is unknown.

The H IX V-3 was later shipped to USA, and is now in the Smithsonian collection, awaiting restoration.

Good job boys, topic merged with early one.

If this is not the most cromprensive topic about the Horten I have no idea what could it be.

this was one of the first “stelth” aircraft but it was not designed with that in mind, that was just a bonus. I believe there was airplane made in the 30’s that was covered with thin clear plastic and not cloth so that it would be hard to spot. ill post more about it as i find it.

You’re probably thinking of the Taube monoplane of about 1910.

this was one of the first “stelth” aircraft but it was not designed with that in mind, that was just a bonus. I believe there was airplane made in the 30’s that was covered with thin clear plastic and not cloth so that it would be hard to spot. ill post more about it as i find it.

There was a russian stealth project in mid 1930s. The wing and fuselage were barely vissible from certain angles from below.

Probably you are talking about that.

Letter devoted to Herr Horten, with some seriuos ortographics mistakes.

Oh great thing you did with the topic Panzerknacker, I like it.

Yes the sad thing is that the Ho-229 flying wing is still awaiting the restoration work it so needed.

I would have loved to talk to one of the Horten brothers.

Many people spell the last name of the Horten’s wrong and I must say I also did it myself at a time.

The work the brothers did was great and to think that it was done at that time and even after the war they did a lot of work on aircraft even in Argentina.

The pics of the Ho-229 in the NASM is very sad for me and I let a mag do a article on the aircraft here in SA, but they had a lot of their facts wrong and I did supply them with all of the original information and pictures of the aircraft and where it was today and in what state it is, but when I asked them why they gave the wrong info they said it is what their investigator gave them.

Oh well that is live.

Panzerknacker do you have any more info on some of the other projects the Horten’s did during their designing time?

Sure I do, check this documentry.

http://stage6.divx.com/History---World-War-II/video/1630265/Secret-Luftwaffe-Aircraft-of-WWII

Thanks mate.

My mom dropped cool drink all over the PC and I thus had to get a new one so I was a bit in the dark for a while, but lucky for me the HDD did not get any damage.

Indeed excellent job, honorable gentlemen! You have succeeded in collecting every individual piece of information connected with the wartime work of the Horten brothers, which is absolutely remarkable and utterly unparalleled in the history of the German aircraft production.

Horten brothers not only faithfully remained with the flying wing concept, but they also did that without any support from the large aircraft companies or from the RLM – furthermore, their most important construction and everlasting evidence of their true engineering ingenuity, the one and only Horten Ho IX, was a result of a completely unauthorized, even illegal actions!

After the outbreak of war, Reimar Horten - the youngest brother – was assigned with the duties of a gliding instructor, and that verity practically had incapacitated him to work as a productive airplane designer. In November of 1941, however, General Ernest Udet committed suicide and Walter started to think how to liberate his brother of those duties, and how to ensure the recommencement of previously successfully committed designing activity.

Horten V – true example of the clear, highly streamlined design

Result of his intellectual reconsideration was one of the most important deceptions that took place in the Luftwaffe during the WW 2. Due to his position as an engineering consultant to the Inspector of fighter and ground attack aircraft at RLM, General Kurt-Bertram von Döring, he was able to do it with no questions asked. Within the Fighter Inspectorate under his control he therefore established a top secret unit, known as Sonderkommando 3 (the number referred to the Ho 3 glider built by Reimar) at Gottingen air base. The unit was so secret that only Walter and his brother knew about it!

Of course, official documents mentioned the Sonderkommando 3, but there were numerous special units in the Luftwaffe, and it was unlikely that anybody should become interested in that one. However, the whole affair was awfully risky. If the verity that the Horten brothers are using Luftwaffe funds and facilities to do something on their own has turned out to be notorious, the fate of the designers would be highly unattractive: in those cases court-martial procedure was absolutely assured!

Sonderkommando 3 was headed by Reimar, who was officially employed at the Inspectorate, but with no particular assignment. This gave him plenty of time and funds to accomplish previously envisaged plans. In August of 1940 Horten brothers have observed the first take-off of the rocket powered DFS 194, constructed by Alexander Lippisch at the German Institute for Sailplane Flight. Brothers were greatly impressed with the performance demonstrated by this wooden airplane, that flew with a speed not much less than the magic 1000 km/h. They agreed that it surely would be possible to break that barrier, and that their airplane should do that. Walter though of it in terms of a new airplane for the Luftwaffe, faster and better than all other designs, while Reimar wanted simply to beat Dr. Lippisch within the frantic engineering pursuit oriented toward braking the sound barrier.

On the way back to Gottingen the brothers agreed that rocket propulsion, with its inherent limitations, was unsuitable for a regular combat airplane. They decided that the newly developed jet engines would be a better choice for their needs. It was Walter’s duty to secure these engines, and they actually needed two such engines, because they considered that twin-engine layout was the better one.

In early 1943 Walter took part in a meeting with Reichsmarschall Hermann Göring, where the Reichsmarschall demanded increased fighter and fighter-bomber production without “duplication”. According to his views, it was a frequent case that several companies were building various aircraft for the same use, and this practice was wrong. Göring said that he will not support such a nonsense, and the only thing he wants is one single airplane, capable to carry 1000 kg of bombs over 1000 km distance with 1000 km/h speed. Aforesaid airplane also should have been able to participate in a normal fighter combat activity. During the permanently heated discussion the Reichsmarschall declared that he would offer 500.000 Reichmarks to the first company able to offer such an aircraft.

Horten Ho 229A-1 – artistic imagination of a post-WW2 line of business

Walter Horten immediately contacted his brother, who then prepared a large, 20-page wide document, describing the potential airplane, with all subsequent performance calculations. Nominated as Horten Ho 9 fighter/bomber, aforesaid machine was designed to fulfill all previously highlighted requirements, including the exploitation of non-strategic materials in serial production of the airplane. Horten brothers attached general arrangement drawings, even an artist’s impressions of the Ho 9 in flight. Documentation was sent to Generalmajor Ullrich Diesing, the head of the RLM’s planning office, who subsequently sent copies to individual RLM officials and to the DFS for additional evaluation. Reason for all this was Diesing’s unreadiness toward eventual enragement of the Reichsmarschall, and his personal inclination toward additional professional backup of the proposal, before official presentation to the Reichsmarschall Göring. The procedure took half a year.

In August of 1943 the RLM considered the Ho 9 project a very appealing one, and the designers themselves were personally invited by Göring to the meeting that took place at the holiday-residence of the Reichsmarschall - Karinhall. Goring was surprised with the youthful age of his guests (Reimar was 28 years old, and Walter 30). He asked numerous questions about their previous achievements and the roots of their design competence at such young age. When Reimar presented the material about calculated performance, useful load, fuel consumption… etc, and added that the airplane would be built mainly of wood, the Reichsmarschall apparently sprung up from his chair and shouted “do it!”.

After that he called for Erhard Milch and ordered him to give the Hortens 500.000 RM for the development of the Ho 9. When Milch asked with whom the contract is to be signed, Walter asked for one day of delay, after which he met Milch again - this time as a representative of Horten Flugzeugbau GmbH!

The rest is history.

This story represents abbreviation of the original chapter published in a book “German Air Projects 1935-1945, vol. II – Red series” by Marek Ryś, Mushroom Model Publications, Sandomierz, 2004.

The Horten brothers had a great idea of flying wings. They did not go to any school to be able to build or design these aircraft, but they had success with the aircraft they build. I would just like to see if someone can build a replica of the Ho-229 and fly it to see how great it is.

Just a tiny bibliographic remark, my dear Mr. HG: Although only a few details regarding formal education of Horten brothers are currently available, it is known that they actually have been raised in a highly academic atmosphere - their father, late Prof. Dr. Max Horten, was renowned professor of oriental sciences and cultures at the university of Bonn.

Furthermore, according to “Warplanes of the Third Reich”, Doubleday and Co., 1970, they actually have had a brief stint at the Technical University in Bonn back in 1938, before they returned to the Luftwaffe.

After World War II, Dr. Reimar Horten had acquired his academic degree at the University of Bonn in 1946, and later went away to the Republic of Argentina, where he worked as a designer in the DINFIA (National Directory of Aeronautical Construction and Investigation, and also labored together with Dr. Ing. Kurt Tank.

I understand what you mean mate, but I meant they did not have any education in designing aircraft. It is a shame that the Horten brothers did not have a greater impact after the war.

You sure do know a lot about the Horten brothers. I saw the NASM in Washington DC has all the interview tapes that was done with the Horten brothers about all of their work, but most of it is in German.

Didnt they go to Argentina after the war and design planes similar to that of the hortem bombers?

Anybody know why the 229 in storage in USA is not assembled?!

(That fact is the weirdest thing concerned with aviation ever)