Finally, after a wild day, I was able to finish this post… So here we go, honorable ladies and gentlemen:

I agree with the librarian the reasons for not providing the german tanks with the diesel engines they needed was mainly a matter of politics and coordination.

Thank you, my dear Mr. Gojulas. You see, actually the main problem with the German preparations for the war was that no fixed organization was set up to carry out the plans!

When Hitler announced the Four Year Plan back there at the NSDAP Congress in September of 1936, he said that Germany …must be independent of foreign countries for those materials which she could produce herself, either by chemical means or by mining." This would reserve foreign exchange for food and materials, which could not be so produced.

Göring was appointed as Administrator for the Four Year Plan by a decree in October of 1936, and he defined the objects of the plan as being to increase self-sufficiency while continuing rearmament at a rapid pace. The production of synthetic fuels was to be pursued, with the aim of meeting by 1939 all the fuel needs of the mobilization plan, 50 % of the rubber needs, 30 % of the textiles, and 33 % of the animal fats.

Göring declared that his tasks, and those of agencies which he set up, were to provide leadership, initiative and drive – but not the administration! :shock:

Furthermore – organizations created under the plan were typical of the Third Reich in their fluidity, total improvisation and overlapping. Schacht remained as Minister of Economics until November of 1937 and constantly continued to oppose the self-sufficiency aspects of the Four Year Plan, with the support of greedy business circles, banks, and large part of the steel industry.

Under the terms of the Four Year Plan the production of synthetic materials was ment to cope with all potential problems. But it always failed to achieve the target! Self sufficiency in oil within 18 months was Hitler’s aim in 1936. By 1937the date was postponed for 1940. In 1940 it vanished into the future! Production reached 2.3 million tons in 1939, or only a quarter of estimated mobiliyation needs! In 1943 production achieved 5.7 million tons, or about half of the supplies planned for that year. German program was technically completely sound, but it was extremely expensive, demanding heavy capital investments, and big construction agenda. However, without decisive administrative will and skilled professionals concentrated in a specialized, all-powerful agency or workgroup (like that notorious “Speer’s Kindergarten” within the Ministry of Armaments and Munition!) capable to carry out all previously established plans, everything represented a lost battle even before the stage show started.

Are those “compact” ?

Oh, you are interested only for compact designs, my dear Mr. Panzerknacker? No problem – we have for you some highly compact Diesel engines in our Rarity Cabinet!

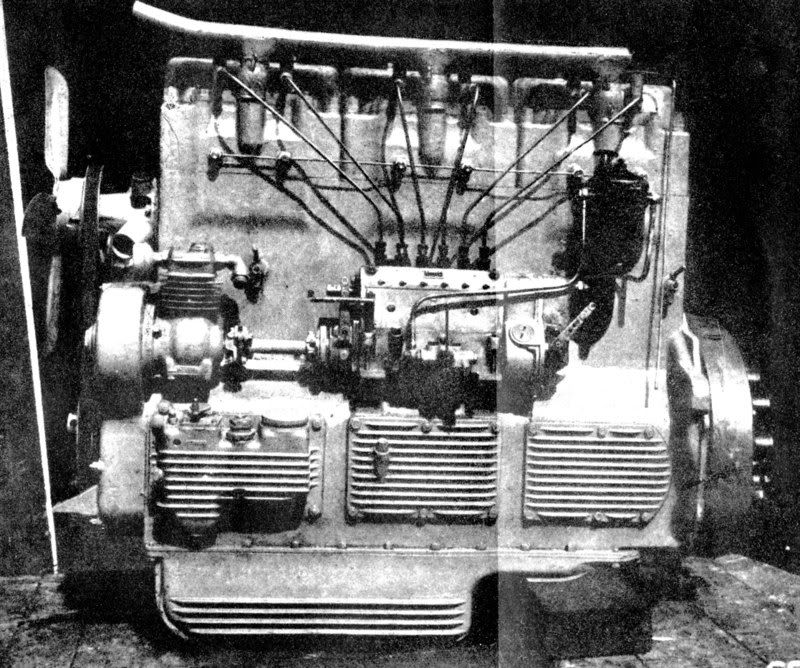

Take for example this light (yes - cylinder heads, crankcase, cylinder blocks and pistons are manufactured out of different aluminum alloys!) piece of mechanical perfection, which arrived in 1942, the Saurer HDV:

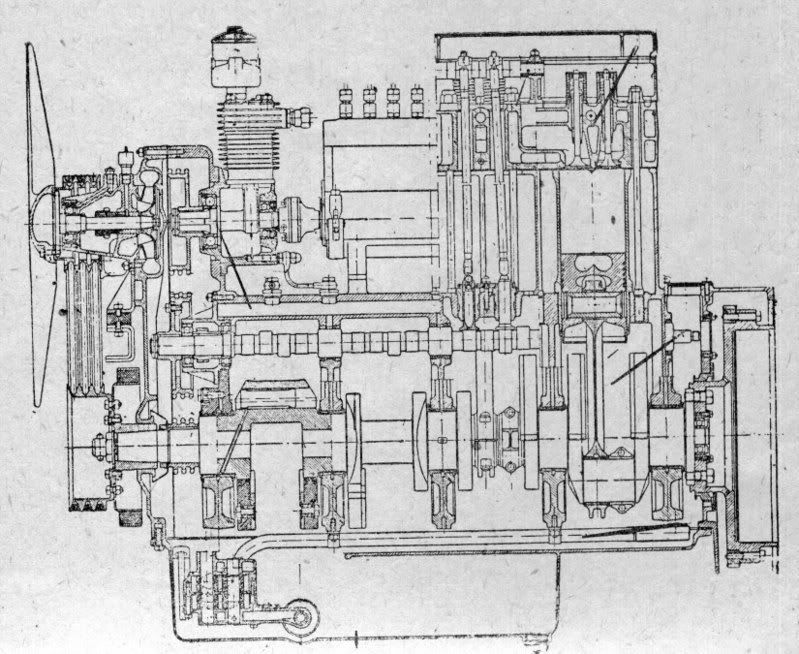

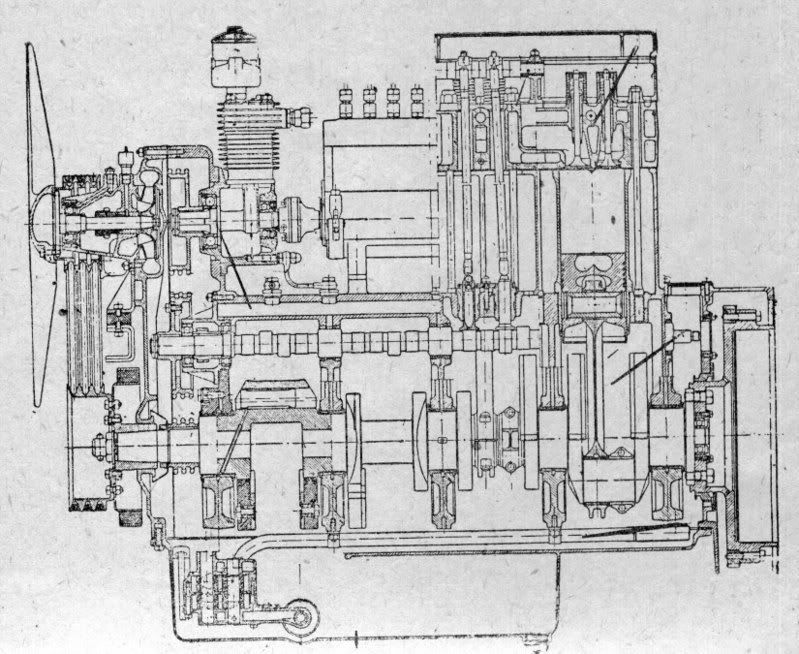

Saurer HDV – longitudinal cross section

This 8 cylinder (V 90), 10,6 Liters, 4-stroke Diesel was equipped with a truly magnificently efficient dual turbulence chamber direct injection (bore x stroke 110/140 mm), mechanically driven supercharger, compression ratio 17,5 : 1 and power output of 200 HP at 2200 RPM, total weight of 630 kg, and capable to achieve an astonishingly low specific fuel consumption of 165 g/HP-Hour!

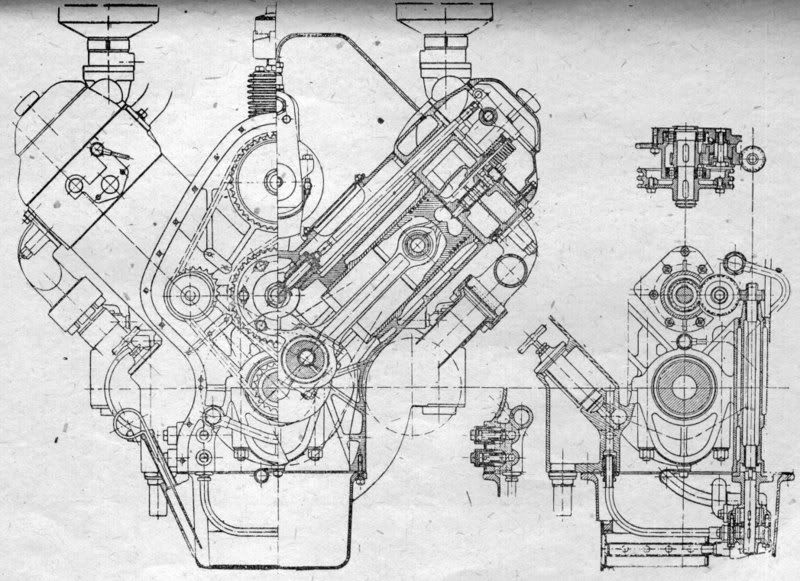

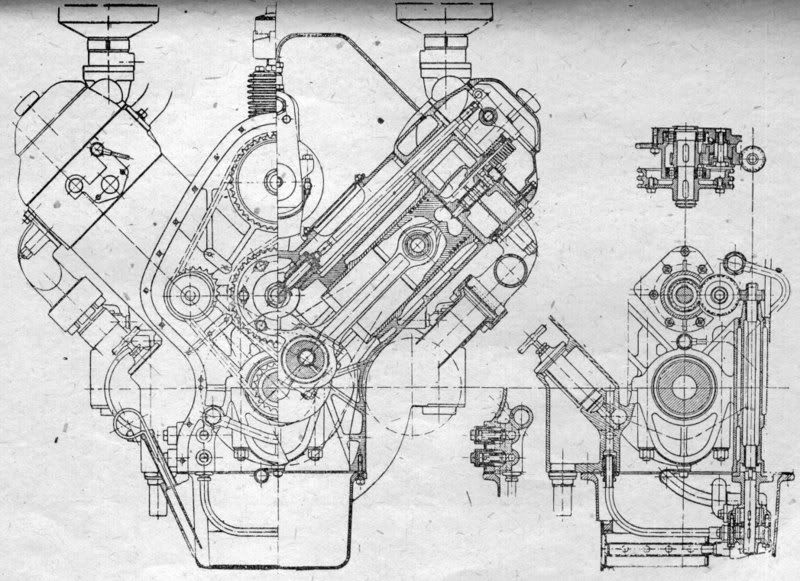

Saurer HDV – transversal cross section

Pretty nice power unit for the Schwerer Zugkraftwagen Sd.Kfz.9, isn’t it, my dear Mr. Panzerknacker?

However, you are probably more interested for the eventual tank engines. No problem at all – we have further examples of the Austrian engineering ingenuity as well. In that case, an truly incredible and sadly forgotten machine, produced in only 25 pieces from 1943 until 1951, and observable here, my dear Mr. Panzerknacker:

http://dh5eah.toxisch.net/diverses/dieseltechnik_am_bodensee2006.pdf

Yes, that is another aluminum construction – Saurer CVDL, an 16 liter, 4-stroke Diesel engine with direct injection, equipped with two independent Brown Bowery & Cie. turbo-superchargers, and capable to produce 300 HP at 2200 RPM. Specific fuel consumption in this case was 160g/HP-Hour.

Compare these numbers with those relating to legendary Maybach HL 120 TRM V12, and you will see that Diesels were at least as much developed as petrol engines, furthermore – in certain aspects they were absolutely outstanding! Just imagine, for example, those never realized operational range possibilities of the PzKpfw IV family equipped with this last Diesel engine, my dear Mr. Panzerknacker. I am assuring you that tactical advantages are almost incredible…

But, if I remembered that well, you dislike those aluminum solutions.

Well then, how about some other, more classicistic solutions for armored vehicles? You know, we have some other offers as well.

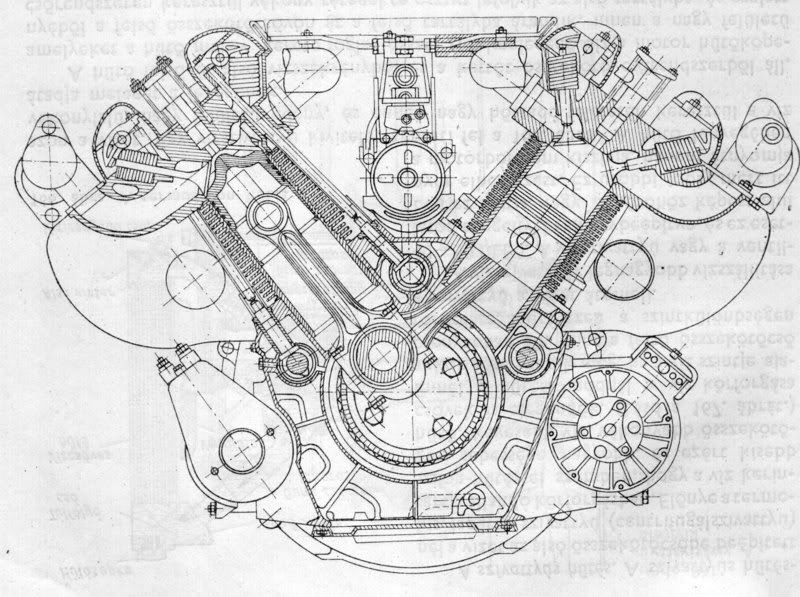

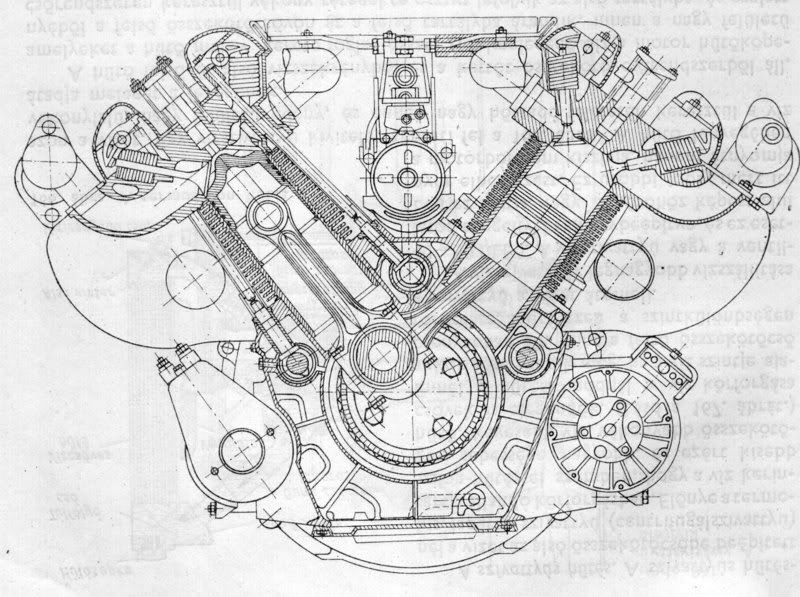

Take for example, this Tatra V 910 – an mechanical icon designed for the most severe working conditions, which earned its legendary reputation due to its celebrated reliability, brawny nature, and incredible modesty. An air-cooled, V 12 Diesel engine with a direct fuel injection, 110 mm bore and 130mm stroke, 14,8 Liters of displacement, compression ratio of 16,5:1, 210 HP at 2250 RPM - and without radiator, water pump, head gaskets, hoses, or thermostats, and completely capable to start on -40 degrees of Centigrade somewhere in Eastern Siberia.

Tatra V 910

Almost perfect standardized power unit for certain military vehicles, my dear Mr. Panzerknacker, isn’t it? Trucks, armored cars, auxiliary vehicles, even light tanks… But, yet again, sorrowfully unexploited…

And now comes the most interesting party of this story, directly connected with our main theme in this thread. Unbeliveably, my dear Mr. Panzerknacker, but actually there were completely serious plans for employment of a modified, 18-cylinder variant of this engine (additional 6-cylinder bank added in the center - so called “three bank”, or “W” engine configuration!) for the Tiger tank! :shock:

Well, that’s all for today. In the meantime, as always – all the best!